Home » Civil Engineering » Noise Reduction Gasket

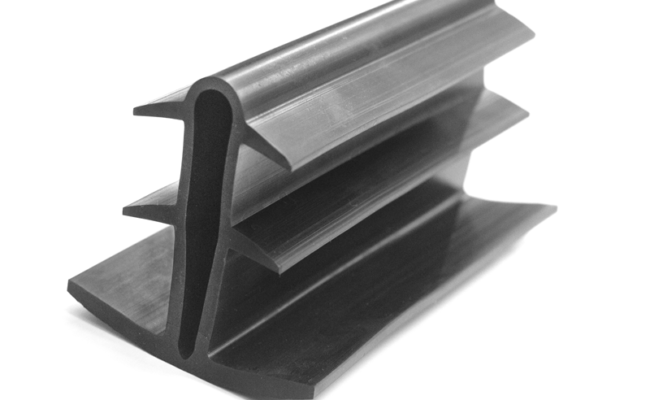

Boss Polymer specialise in the design and manufacture of noise barrier gaskets which are essential when noise and vibration reduction is necessary.

Traditional methods required skilled personnel to wait for suitable weather conditions to enable them to build up layers of caulking compound to fill wide and uneven gaps in a vertical area. This antiquated method produces a lot of rubbish on site.

The Boss Polymer engineers designed the SpineSeal®, a 30 year weather resistant seal that can be installed efficiently and effectively in any weather conditions. Made from high-grade silicone, the SpineSeal® was installed up to two times faster than traditional acoustic fencing. The choice of silicone as the recommended material was due to its ease of installation, longevity and the opportunity to offer a 30 year warranty.

Noise barrier gaskets block and defuse sounds such as traffic, industry and domestic noise, originating from the source. Boss Polymer ensures that all fencing is designed to ensure it adheres to standard statutory regulation and design constraints.

Boss Polymers noise barrier gaskets have been used in such applications as the construction of freeways and highways as well as main roads with high traffic efficiency and power enclosures and commercial properties adjoining the residential dwellings adjacent to these dwellings. Boss Polymer also provides noise barriers to new housing estates, developer funded projects and railway sites to reduce the potential for noise pollution.

Contact the Boss team to discuss your unique Noise Reduction Gasket requirements. View our extensive range of rubber extrusions & profiles, plastic extrusions & profiles, and silicone extrusions & profiles.

View Catalogue